The Internet of Things (IoT) produces staggering amounts of data daily. Real-time analysis of this data helps businesses address the demands of consumers in today’s always-on economy.

Supply chain management exemplifies IoT impact on manufacturing industries. With a multitude of moving parts like vehicles, shipping containers, and packages functioning as sources of data, companies need more advanced methods for ingesting and analyzing IoT data.

Most companies use descriptive analytics, but the above statistic from Gartner reinforces that descriptive is no longer sufficient. Data analytics is evolving to predictive, and will eventually move even further beyond that to prescriptive analytics. Supply chain companies must modify their strategies to include these advanced analytics.

At Gartner Catalyst earlier this year, we released MemEx, a showcase application modeling predictive analytics for global supply chain management. MemEx highlights how enterprises like FedEx, Amazon, and DHL can implement advanced analytics to improve logistical operations.

About MemEx

MemEx uses advanced analytics to predict throughput of supply chain warehouses.

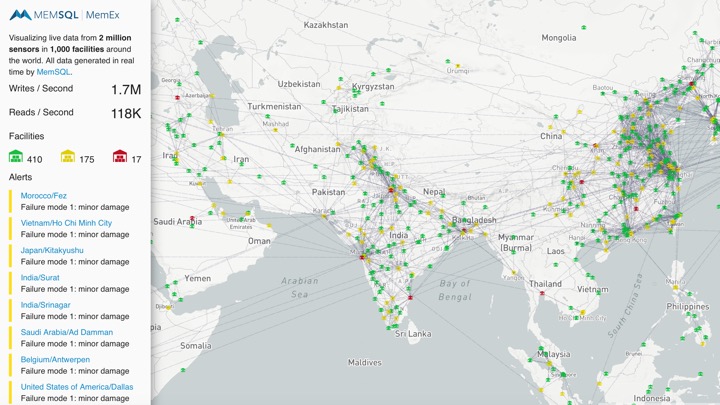

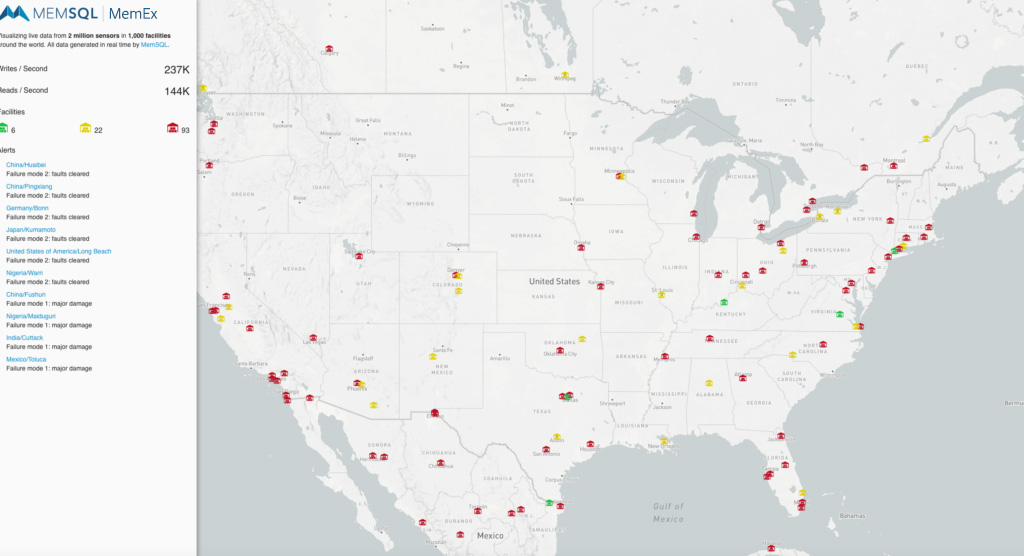

The application processes and analyzes 2 million simulated data points based on 2,000 sensors across 1,000 warehouses globally.

These sensors appear on production lines and conveyor belts in and around each warehouse, measuring operational health of the machines with readings such as temperature or electrical current output. By harnessing this critical sensor data in real time, supply chain organizations can predict lapses in throughput and plan accordingly.

MemEx Architecture

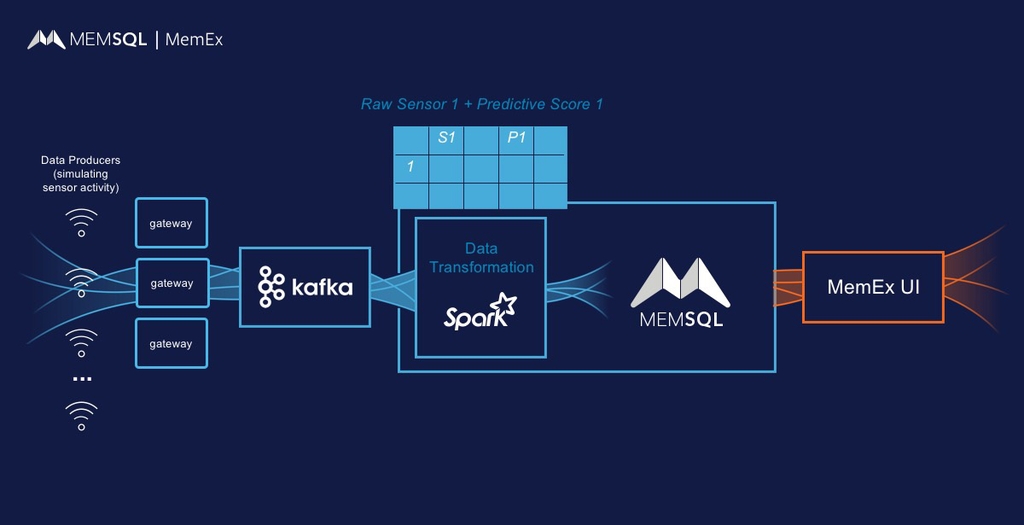

MemEx, powered by the SingleStore database platform, includes:

- Streamliner, our integrated Apache Spark solution

- Ops, the web interface for cluster deployment, management, and monitoring

- A set of simulated data producers written in Python

- Apache Kafka

- Javascript-based User Interface (UI).

The architecture of MemEx is shown below:

Data producers simulate sensor activity, pushing approximately 2 million data points every second from sensors on warehouse machinery. Sensor data is sent to an Apache Kafka message queue, which is processed by a SingleStore Streamliner data pipeline. The pipeline predicts throughput of each warehouse using a pre-trained machine learning model. The sensor data and warehouse states are stored in SingleStore and further analyzed to determine the overall health of the supply chain.

Finally, the MemEx UI queries the SingleStore database to display states in the web interface. The gears indicating warehouse functionality shift colors from red to yellow to green based on predicted throughput. Additionally, geolocation of each warehouse is stored in a SingleStore table, and queried dynamically based on user changes to the map area in view. These queries, and subsequent visual display, depend on the map geography and zoom level selected by the user.

By predicting risk of production failures, MemEx enables enterprises to react to their businesses in real time, make supply adjustments, and ultimately drive revenue.

The Real-Time Future of Supply Chain Management

Many companies on the forefront of IoT already or will soon incorporate machine learning into their businesses: Amazon proposes automated drone deliveries, Fedex provides real-time package tracking, and Tesla released connected vehicles capable of autonomously driving. The future of supply chain and logistics companies depends on predictive analytics. Embracing advanced analytics brings businesses one step closer to running completely autonomous supply chain functions.

MemEx provides a realistic view into the capabilities of using real-time applications with predictive analytics to draw businesses into the future of connected things.

Watch a live demonstration of MemEx